Porsche Press Release Database

Current Press releases

The Porsche 918 Spyder: High-tech craftsmanship

Porsche 918 Spyder manufactory, part I "Manufacturing" and "suppliers"

Stuttgart

. The

A good four years ago, Michael Drolshagen was given the responsibility of designing and building a manufactory for the

A new polish for the former paint shop

24 months later, the manufactory was settled in its central location at Plant 2 in Zuffenhausen. Anyone who sets foot in the former paint shop for series-production sports cars on the second floor will realize immediately that the project team has created a space that comes very close to the original idea proposed by the Spyder Director of Production.

Focused and perfectly silent, the

Everywhere is neat and tidy. No cables spill over into the pathways between the workstations. This is also because the aim from the outset was to rely exclusively on cordless tools for the construction of plug-in-hybrid sports cars. The Bluetooth-controlled cordless screwdrivers are an example of this philosophy in action: These tools are virtually silent, they offer technicians flexibility at the workstation and they reduce the risk of damage to components. Coupling the screwdrivers with the database also ensures that the stored torque values are reliably complied with and can be documented and checked at any time.

The best of both worlds

The uncompromising approach to quality management embodied by the process of checking and documenting torque values also explains the decision to locate the Spyder production line at the Zuffenhausen plant. It goes without saying that the plant also offers an emotive connection, given its links with the origin of the 911 legend,

In addition to its infrastructure, the Zuffenhausen plant offers another crucial benefit for the 918 manufactory: the employees. Around 3,500 people work on vehicle assembly at the plant and nowhere else would it have been possible to rely on a pool of such highly qualified specialists from the development, vehicle equipment, body assembly, paint finishing, assembly and drive unit fields.

Women and men from around 14 different countries were eventually assigned the coveted spots on the Spyder 918 production line. The ages in the team range from 21 to 56 years, with professional experience of between 6 and 40 years. The members of the team all come from the 911 production line, and many of them have already worked on the production of motorsport vehicles or prototype production. With all their expertise and passion, this varied team is what will guarantee that exactly 918 units of the

Production in line with the herringbone model

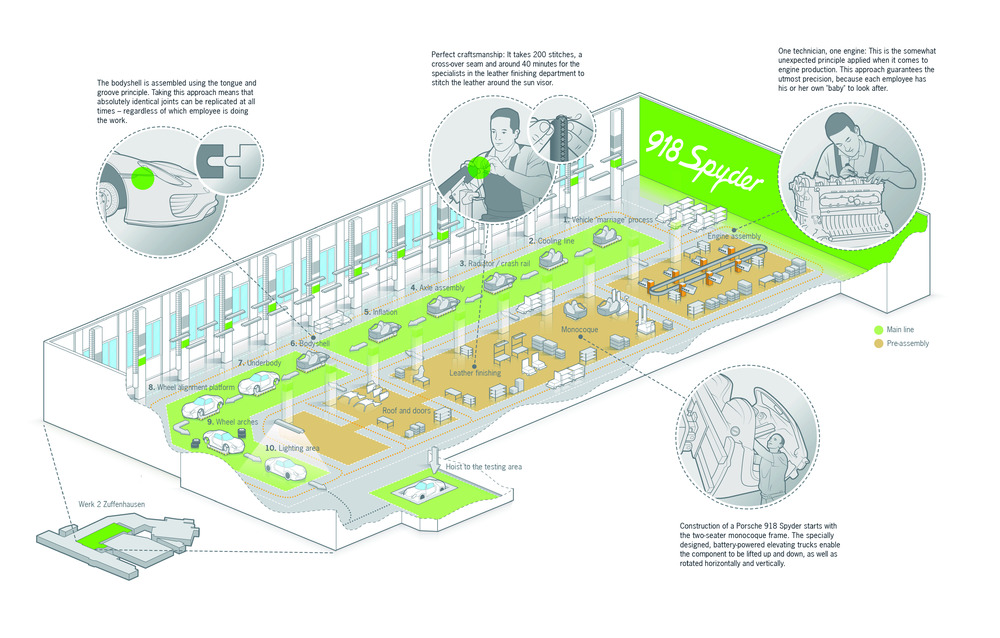

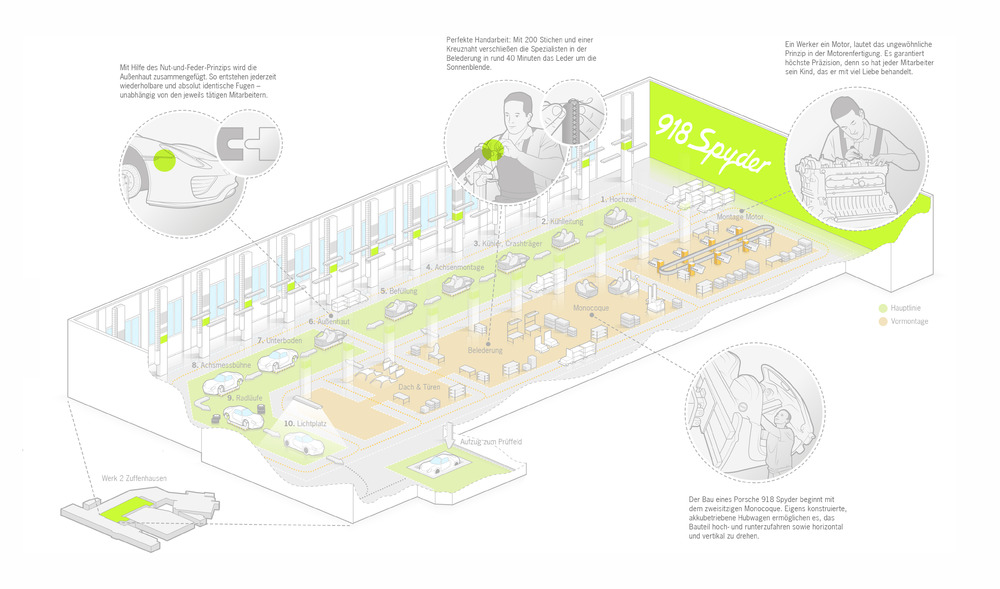

The starting signal for the assembly of the first series production vehicle sounded on September 18, 2013. Before that, a team of 25 employees had already produced 25 prototypes and eight pilot vehicles. The L-shaped production line proved its worth during this introductory phase: "We have practically the entire value chain within this 4000-square-metre area", says Michael Drolshagen. "This in itself is unique."

The vehicles pass through 18 stations before they are driven almost silently into the elevator in pure electric mode so that they can then be put through the final tests in the test facility located two floors below.

During the production process, the

Quality assurance is the top priority

Around 100 hours of production time – including detailed quality control procedures – go into the entire process of getting a

New methods and patent applications in the pipeline

With the

It is difficult to pinpoint individual "stand-out stations", but the assembly of the monocoque, the engines, the leather finish and the assembly of the body shell all fall into four production stages that underline the manufactory philosophy particularly effectively.

The monocoque as the starting point

The fact that the construction of every

The activities that take place on the engine line are also rather unusual. Based on the philosophy of "one technician, one engine", the units, constructed in line with lightweight technology principles, develop each one of their contours as they pass through the eight stations. The work takes 20 hours to complete, and by the end the 140-kg engines are the work of a single employee. Following this approach, in line with the

High standards for specific skills

Absolute precision is the key on the production line – the tasks completed by the production staff are all designed to highlight the extremely high standards applied to their work. After all, this is the only way to fulfill the equally discerning expectations of

In order to give 918 Spyder buyers pure joy, it was of course necessary to give the manufactory its own leather finishing department. Those who have seen with their own eyes how the vehicle interior specialists stitch the leather around the sun visor in forty minutes with a steady hand in 200 precise stitches and finally secure their work with a cross-over seam will definitely understand the level of quality required for a sports car to labeled "hand-made in Germany".

Numerous standards have found their way into the production process to ensure that the best possible result is achieved every time, regardless of the technician involved. These standards can relate to anything from standardized load carriers through to plug-and-play-principles, all of which ensure that components are installed in a uniform manner with clearances that are precise to the millimetre. The results of the standardized approach become especially evident when the side sections and door sills are fitted, as the tongue and groove principle allows absolutely identical joints to be replicated at all times.

Small and large-scale production at the highest level

There is no doubt about it: The

The experiment has been a success. In Zuffenhausen, the sports car manufacturer is providing clear evidence that the production of small-series and large-series vehicles is possible "in close proximity and at the very highest level". This knowledge offers new prospects not just for those involved in the project, but also the company as a whole.

About Michael Drolshagen:

Industrial engineer Michael Drolshagen has worked at Dr. Ing. h. c. F.

The suppliers:

The

• Alfing Kessler GmbH (Aalen-Wasseralfingen, Germany): lightweight crankshaft with central oil feed

• c2i s.r.o. (Dunajska Streda, Slovakia): rear mounting bracket featuring RTM technology, luggage compartment tray in prepreg format and CFRP radiator frame for the front and rear

• Connova AG (Villmergen, Schweiz): heat protection

• Eissmann Cotesa GmbH (Mittweida, Germany): CFK components such as central control unit and glove compartment fitting, dashboard carrier and door panel carrier made from visible carbon fibre

• GKN Driveline GmbH (Offenbach, Germany, and Brunneck, Italy): front axle module (clutch and drive shaft)Magna Steyr Battery Systems GmbH & Co OG (Graz, Austria): 12-V lightweight main power supply battery featuring LiFePO4 technology

• MHG Fahrzeugtechnik GmbH/Proseria (Heubach, Germany): INCONEL® exhaust system, coolant expansion tank

• Mubea Carbo Tech GmbH (Salzburg, Austria): Monocoque (RTM component)S1nn GmbH & Co. KG (Stuttgart, Germany): HTML5-compatible infotainment system with tuner, media player, telephone, navigation system and vehicle functions (Automatic Distance Regulation [ADR] – display and domain controller)

• Simfy AG (Berlin, Germany): APP based flat rate for music

• Oerlikon/Metco AG (Winterthur/Wohlen, Switzerland): Plasma coating for the crankcase

918 Spyder: Fuel consumption combined 3.1 – 3.0 l/100 km; CO2 emissions 72 – 70 g/km; electricity consumption (combined) 12.7 kWh/100 km

GO

5/1/2015

![[+]](https://files.porsche.com/filestore/news/international-de/none/229889/headthumbnail1/4d28c269-94e5-11e4-9265-001a64c55f5c/The-Porsche-918-Spyder-High-tech-craftsmanship.jpg)

![[+]](https://files.porsche.com/filestore/news/international-de/none/229889/headthumbnail2/4d28c26b-94e5-11e4-9265-001a64c55f5c/The-Porsche-918-Spyder-High-tech-craftsmanship.jpg)

![[+]](https://files.porsche.com/filestore/news/international-de/none/229889/headthumbnail3/4d28c26d-94e5-11e4-9265-001a64c55f5c/The-Porsche-918-Spyder-High-tech-craftsmanship.jpg)

![[+]](https://files.porsche.com/filestore/news/international-de/none/229889/headthumbnail4/4d28c26f-94e5-11e4-9265-001a64c55f5c/The-Porsche-918-Spyder-High-tech-craftsmanship.jpg)

![[+]](https://files.porsche.com/filestore/news/international-de/none/229889/headthumbnail5/4d28c271-94e5-11e4-9265-001a64c55f5c/The-Porsche-918-Spyder-High-tech-craftsmanship.jpg)