Press releases

Current Press releases

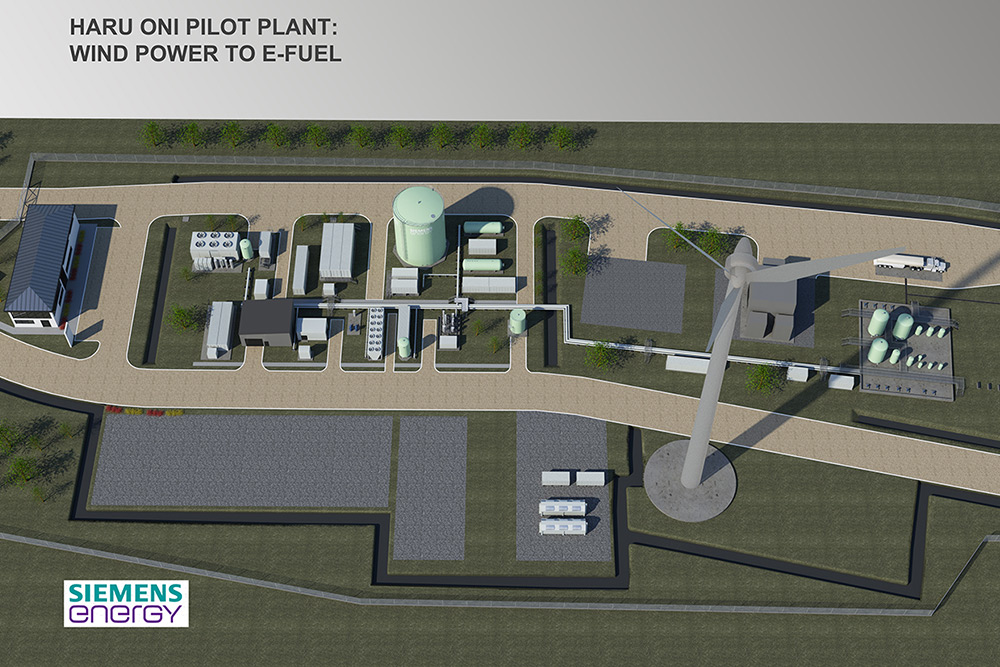

Porsche and Siemens Energy, with partners, advance climate-neutral e-fuel developmentWorld’s first integrated commercial plant for producing climate-neutral fuel being built in Chile

Shanghai/Stuttgart. Sports car manufacturer

The “Haru Oni” pilot project in Magallanes Province takes advantage of the excellent wind conditions in southern Chile to produce climate-neutral fuel with the aid of green wind power. As part of Germany’s national hydrogen strategy, to support the project Siemens Energy will get a grant of some 8 million euros from the Federal Ministry for Economic Affairs and Energy, the ministry announced in last week. Additionally,

Chairman of the

As the fuel’s main customer,

On the journey to full electric mobility, which

Christian Bruch, CEO von Siemens Energy: “Establishing a sustainable energy economy is going to require some rethinking. Renewable energy will no longer be produced only where it’s needed, but where natural resources like wind and sun are available on a massive scale. So new supply chains are going to arise all over the world to carry renewable energy from one region to another. That’s especially important for Germany, which – bottom-line – has to import energy if it’s going to meet its nationwide demand. Hydrogen will come to play an increasingly important role in storing and transporting energy. Which is why the German government’s support for the project is an important signal.”

Federal Economy Minister Peter Altmaier: “Hydrogen is a key component for successfully carrying out the energy transformation in every sector. That’s why, with the National Hydrogen Strategy, we aim to take advantage of the opportunities that hydrogen offers for the climate, energy and economic policy. We know we won’t be able to cover our national demand out of domestic production alone, and will need international partnerships. So I’m very pleased to see that

Siemens Energy is a co-developer of the “Haru Oni” project (also known as HIF project), and is serving as a systems integrator to cover the entire value chain – from power generation using Siemens Gamesa wind turbines, to producing green hydrogen, to conversion into synthetic fuel. The company’s flexible PEM (PEM = Proton Exchange Membrane) electrolysis is ideally suited for using volatile wind power.

AME is the primary developer and owner of the HIF (Highly Innovative Fuels) project company. Enel is a co-funder of the plant, with a focus on wind power and electrolysis. ENAP will support the project by providing operating staff and with maintenance and logistics.

Chile, with its excellent climate conditions for wind power and the associated low cost of electricity, has a very high potential in international terms for producing, exporting and locally using green hydrogen. To generate green hydrogen, electrolyzers use wind power to dissociate water into its two components, oxygen and hydrogen. In a second step, plans call for filtering CO2 out of the air and then combining it with the green hydrogen to form synthetic methanol. The result is renewable methanol, which can be converted into climate-friendly fuel using an MTG (Methanol To Gasoline) technology to be licensed and supported by ExxonMobil.

Michael Steiner: “

Michael Steiner, Member of the

1. The "e" in e-fuels stands for "electric". What do e-fuels have to do with electric mobility?

Michael Steiner: eFuels are essentially a second sustainable route to electric mobility. Just like in a BEV, renewable electric energy is also used for propulsion by a vehicle with a combustion engine that is powered with eFuels. The difference is that the electric energy in the BEV is stored in the battery in its electrochemical form, whereas in eFuels it is stored as liquid hydrocarbons.

2. What are eFuels and how are they manufactured?

Michael Steiner: eFuels are synthetic liquid fuels produced from hydrogen (H2) and carbon dioxide (CO2), using electricity generated from renewable energies (solar and wind energy). The required hydrogen is extracted from water by electrolysis. CO2 is extracted straight from the air using the Direct Air Capturing procedure. What is known as e-methanol is produced from hydrogen and CO2 in a first stage. In just one additional synthesis step, e-methanol is further processed to produce e-fuel (e-petrol). This fuel can then be used in all conventional petrol engines. The entire chain is virtually CO2 -neutral as only renewable energy is used for the production of e-fuels and the quantity of CO2 generated when burning the e-fuel in the engine is restricted to the amount previously extracted from the air.

3. What are the benefits of eFuels?

Michael Steiner: If e-fuels are manufactured using only renewable energy, their use can significantly reduce the emissions of fossil CO2 from pure combustion engine cars. Depending on availability, this can initially be achieved by blending e-fuels with conventional fuel, and later also with pure e-fuel. In addition, the existing infrastructure for storage and distribution of the fuel can still be used. Furthermore, the synthetic manufacture of e-fuels makes targeted fuel design possible.

4. Why is

Michael Steiner: On the journey to full electric mobility, which

5. Are eFuels not in competition with electric mobility?

Michael Steiner:

6. Is there enough renewable energy available in Germany to produce the required quantities of eFuels?

Michael Steiner: “Green” electricity will be available in Germany only to a limited extent for quite a while. It should therefore be used to charge fully electric cars like the

One example: a wind turbine in the right location – for example, in South America – can supply approximately four times as much energy as electricity generated from wind energy in Germany. It is therefore expedient to relocate the hydrogen production to such regions. The synthesis of the hydrogen and the CO2 from the air into methanol and then to e-fuel, an easily transportable liquid, should then be carried out locally. This is because it is not possible to transport the electricity generated there directly to Germany and to use it in electric cars.

All in all, an overall well-to-wheel efficiency – in other words, from the energy source, the wind turbine in our example, to the wheel of the car – can be realised. This is on a similar scale to that of battery electric vehicles, which are charged up straight from the green electricity generated in Germany.

7. How environmentally friendly are eFuels compared with other alternative fuels from biological sources such as E10 or biodiesel?

Michael Steiner: Biofuels require much more water and, due to their nature, are also restricted in terms of quantity. Nevertheless, they will continue to have a firm share, provided they do not compete with food production or contribute to deforestation. As they are already available today as admixture components, they contribute to achieving climate targets.

8. What do eFuels cost?

Michael Steiner: At the moment, the price for one litre of eFuel is of course much higher than for conventional fossil fuel. But the price will fall if, in future, eFuels are manufactured industrially on a large scale, instead of in small quantities in pilot installations. In the medium term, prices will settle at comparable levels in conjunction with increasing CO2 pricing for fossil fuels. It also reduces the dependence on ever decreasing fossil fuel resources.

9. What is

Michael Steiner: We are monitoring fuel cell research very closely even though we are not developing any ourselves. It is a very interesting technology – suitable for heavier long-distance vehicles used for freight transport, for example. However, a fuel cell is not really suitable for our model range – mainly for packaging reasons. But also because the dynamic performance requirements and cooling for sports cars have not yet been satisfactorily met. Furthermore, hydrogen filling stations would require new infrastructure that would mean further investments – on top of the development of the electric vehicle charging infrastructure.

Nonetheless, we are looking closely at hydrogen production as it is the basis for one eFuel that can be distributed using the existing service station infrastructure. It can also be used to operate our fully fledged combustion engines as well as our ever increasing range of plug-in hybrids CO2-neutrally. In principle, eFuels are green hydrogen which has been subjected to further processing.

10. But initially, a great deal of energy must be used to manufacture eFuels. Is that sensible or efficient?

Michael Steiner: Up to now, efficiency criteria have dominated the development of technical systems because consumption-driven criteria were the most important when using finite resources – such as petroleum. After all, we were trying to make reserves last as long as possible. But this model is now changing. The transition to renewable and abundant, regionally available energy from wind, sun and water power gives us the chance to prioritise sustainability even more. Pure efficiency must and will include sustainable generation. Increased energy consumption in the overall process chain is quite acceptable if the sustainability balance sheet is positive. Furthermore, increased energy consumption does not necessarily mean more investment, as you can see from the fact that one and the same wind turbine can produce so much more energy, depending on its location – Germany or South America.

11. When will eFuels be available on the market in significant quantities? Is it possible to say when eFuels will completely replace fossil fuels?

Michael Steiner: Significant quantities of the fuel could be available in the EU in as little as 10 years, provided the necessary willingness to invest and a positive political and regulatory environment are available.

12. What is

Michael Steiner:

13. Which partners is

Michael Steiner: Siemens Energy is the co-developer of the project and, as a system integrator, covers the entire value creation chain – from power generation with Siemens Gamesa wind turbines and the production of green hydrogen to the conversion to synthetic fuel. AME is the principal developer, as well as owner of the project company HIF (Highly Innovative Fuels). Enel is co-financing the plant with a focus on wind energy and electrolysis. ENAP is supporting the project with operating staff as well as maintenance and logistics. The result: green methanol that is converted to environmentally-friendly fuel with the help of MTG (MTG = Methanol to Gasoline) technology licensed by ExxonMobil.

14. Exactly how does the process of converting methanol to a fuel for petrol engines work?

Michael Steiner: Methanol to gasoline (MTG) is a chemical reaction process used to produce petrol from methanol in a synthetic process. The idea is that methanol is fed from above into a tube filled with catalyst material. In the first step, methanol is converted into dimethyl ether in a catalytic process at pressures between 14 and 24 bar and temperatures around 400°C。Following this, either still in the same tube or in a separate tube, the dimethyl ether is converted highly selectively into a petrol fuel using a zeolite catalyst in the same temperature and pressure range. E-fuel can be directly produced with a high degree of selectivity by varying the process conditions and catalyst.

15. Where exactly is this plant in Chile located?

Michael Steiner: The pilot plant is located in the province of Magallanes in Patagonia, the southernmost region of Chile. The nearest large city is Punta Arenas.

16. How much is

Michael Steiner: Initially,

17. What is the annual capacity of the planned pilot plant? How many litres of methanol can be produced there, and how many litres of finished e-fuel can be made from it?

Michael Steiner: In the pilot phase (2021/22) the plant will be able to produce 600 tonnes or 750,000 litres of e-methanol annually. From this, 130,000 litres of e-fuel can be produced annually. These quantities can significantly increase in the planned subsequent phases. In the pilot phase, this is limited to the mentioned 130,000 litres per year. The capacity can then be increased in two steps: to around 55 million litres of e-fuel per year by 2024 and around 550 million litres of e-fuel per year by 2026.

18. I read in a publication that the plant in Chile can produce 750,000 litres of e-methanol per year. But only 130,000 litres of e-fuel will be produced. How is this justified?

Michael Steiner: In order to produce one litre of e-fuel, around 2.5 litres of e-methanol is required. Theoretically, around 300,000 litres of e-fuel can therefore be produced with the e-methanol produced in Chile. The fact that not all the e-methanol will be converted to e-fuel is due to the capacity of the downstream plant for the methanol to gas (MTG) synthesis. In the pilot phase, this is limited to the mentioned 130,000 litres per year. The capacity can then be increased in two steps: to around 55 million litres of e-fuel per year by 2024 and around 550 million litres of e-fuel per year by 2026.

12/11/2020

Further information and pictures for journalists and media representatives can be found on the

![[+]](https://files.porsche.com/filestore/news/china/en/2020-12-11/headthumbnail1/1a95339f-3ba1-11eb-80d0-005056bbdc38/Porsche-and-Siemens-Energy%2c-with-partners%2c-advance-climate-neutral-e-fuel-development.jpg)

![[+]](https://files.porsche.com/filestore/news/china/en/2020-12-11/headthumbnail2/24fc699e-3ba1-11eb-80d0-005056bbdc38/Porsche-and-Siemens-Energy%2c-with-partners%2c-advance-climate-neutral-e-fuel-development.jpg)