“Open-heart surgery": the engine of the 911 T gets back up to speed

When the life rhythm of a long-serving engine is interrupted by a long period of inactivity, this may not have a beneficial effect when it comes to engine performance. Rather, there is a risk that the engine may become the temporary home for undesirable guests. The remains of insect nests still sticking to the engine housing are clear evidence of this. In addition, wind and weather have achieved numerous victories over the metal due to sustained attacks. Nevertheless, the past 38 years have not resulted in any irreparable damage to the engine.

The 911 T undergoes “open-heart surgery”: following the completion of bodywork repairs on the 1973 US Coupé, the experts in the Classic workshop have now turned their attention to the engine. As part of the “Revive the Passion” project, which was jointly initiated by the Porsche Club of America (PCA), Porsche Club Coordination and Porsche Classic, the actual phase of bringing the vehicle “back to life” can therefore now begin. The fully restored vehicle will be raffled off among PCA members and handed over to the new owner at the Porsche Parade in the USA in July this year. The engine, a flat six with a displacement of 2.4 litres, will then deliver the original 140 hp (at 5,600 rpm) to the road and achieve a top speed of 127 mph (205 km/h).

In the Classic workshop, the Porsche specialists first completely dismantled the engine. All parts were then put into the special washing machine. This is necessary, as it is only possible to determine the exact condition of the parts when they are completely clean and free of corrosion and dirt. This work is carried out with minute attention to detail. Some parts, such as the fan cowl, have to undergo a visual inspection for possible cracks. The experts use a sophisticated test method to detect these invisible cracks, which can occur in the crank housing and on the crankshaft, for example. The parts are fluxed in the Porsche development centre in Weissach. Here, electromagnetic steel particles are deposited in the cracks, which are then visible under ultraviolet light. A large number of part measurements are also performed. These measurements check the dimensional accuracy of the cylinder heads as well as of the cylinders and pistons, for example.

At the end of this evaluation process, the experts estimated that the engine mileage was approximately 100,000 miles, not excessive for a 38-year-old engine. The previous owners had also not pushed the engine to its limits. In fact, it was the long standing time that had made it suffer most. On the basis of their experience and the measurement results, the experts then decided on how to proceed with the restoration process.

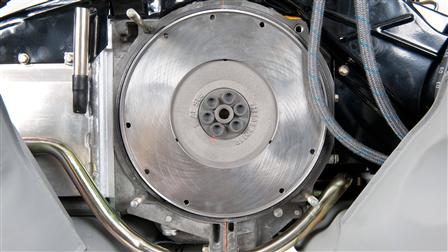

As part of the complete restoration of an engine at Porsche Classic, all bearings, seals and belts are always replaced with new Porsche genuine parts. The same also applies to the timing chains. These do not represent a great cost factor, but they can be accessed only when the engine has been fully opened. The opportunity to replace them is therefore always taken. On the 911 T, the complete electrical system was also replaced, including spark plugs, ignition cables and the engine wiring harness. The non-original exhaust system, oil pump, crankshaft and clutch were also replaced. Overhauled parts such as the mechanical injection pump, distributor, alternator and CDI control unit were installed. Other engine parts were provided with corrosion protection by means of surface treatment. The following processes were used, depending on the part in question: sand blasting with glass powder, galvanising, pickling powder coating and painting.

All of this preparatory work for the successful restoration of the engine is a job for experts with plenty of experience and is also a very time-consuming and complex process. However, this amount of effort is essential for a complete restoration. A complete, new engine from 1973 simply no longer exists. In contrast, a large number of the individual genuine parts are still available. During subsequent assembly and installation, the specialists also made use of old original tools and fixtures.

However, the moment of truth occurs only after assembly. As is usual with a completely new engine, the restored 911 T engine must undergo test operation with a dyno test. The engine cannot expect any special favours due to its age. It has to run like new. For this reason, values such as hp and torque have to be exactly correct. Checks are also made for leaks and general functional capability and various adjustments are performed. The engine then runs at maximum revs – and shines in its old glory.